WhatsApp)

WhatsApp)

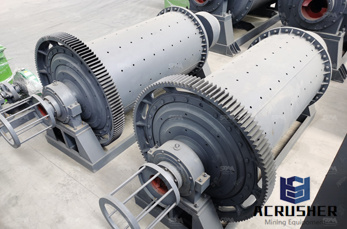

Ball mills designed for long life and minimum ... A ball mill grinds ores and other materials to a typical product ... design feed size to the required product ...

Across International is a leading supplier of laboratory ball mills including planetary ball mills, high energy ball mills, all directional ball mills and ball mill ...

l/d in ball mill designexoticadreamville. design, and the custom could select type of the cavity which has high efficiency, uniformCeramic Ball Mill Ceramic ball mill ...

l/d in ball mill design BINQ Mining: /5 · BALL MILL : definition of BALL MILL and . Definitions of BALL MILL, synonyms, antonyms, derivatives of BALL MILL ...

l d in ball mill design l d in ball mill ... Optimization of continuous ball mills used for finishgrinding of cement by varying the L/D ratio, ball charge filling ...

l/d in ball mill design BINQ Mining. Mills – Osborn South Africa: About Osborn South Africa. NCP Mill Design Capabilities 1. . the L/D ratio of rod mills is ...

Grinding in Ball Mills: Modeling and Process Control ... Grinding in ball mills is an important technological ... The design of a ball mill can vary significantly ...

The optimal ball diameter in a mill 331 In accordance with Eq. 2, the necessary condition for grain comminution is:

CEMENT INDUSTRY Cement Mill Notebook QATAR NATIONAL CEMENT ... for an optimal design of the mill. L/D ... gypsum grinding in a ball mill should be ...

The design of a ball mill can ... Find details about China Ball Mill, ... When the L/D ratio is 2 to 1 or greater, werefer to the mill as a Tube Mill.

Ball mills are commonly used in the manufacture of Portland cement and finer grinding stages of mineral processing, one example being the Sepro tyre drive Grinding Mill.

ATTRITORS AND BALL MILLS HOW THEY WORK ... A typical ball mill has an L/D ratio of :1. Ball mills are filled with spheres or other shapes made of steel or ...

Types of Ball Mills. The Cement Grinding Office. The Art Of Sharing and...Imagination. Home; About Us; Services. Grinding Software; Consultancy; Training Courses;

Slice Mills are identical to the Ball Mills and Ceramic Lined Mills in diameter and design The only ... A typical ball mill has an L/D ratio of :1. ...

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL OPTIMISATION ... Ball mills are predominantly used machines for grinding in the cement ... L/D ratio Mill drive

Calculate and Select Ball Mill Ball Size for . In Grinding, selecting (calculate) ... Machine Design, Machining, Milling

Nov 10, 2012· Mills – Osborn South Africa: About Osborn South Africa. NCP Mill Design Capabilities 1. . the L/D ratio of rod mills is kept within the . Ball mills ...

l/d in ball mill design BINQ Mining: /5 · ball mills length to diameter ratio . The L/D ratio of the ball mill was varied in in the last third of the total ...

modeling the specific grinding energy and ... modelling the specific grinding energy and ballmill scaleup ... the ballmill dimensions (d x l)

A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls ...

What Is The L/d Ratio In A Ball Mill Bing. ... Previous Post Next Post Contents1 advanced comprehensive guide for ball mill design, ...

FL ball mill for cement grinding. ... compartment ball mills is of a rigid design and is supported on a ring of cast steel segments that are bolted

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Formulas Kiln Free download as PDF File ... •Proclaimed Design Volume. ... Ball Mill 3. F = L(1+D)

WhatsApp)

WhatsApp)