WhatsApp)

WhatsApp)

ball milling model. ball milling process model[crusher for sale] The Simulation Analysis for the Milling Process of Ball End, It is difficut to analyze the ball end ...

Process. 48(2), 2012, 329–339 ... then the determination of the optimal ball charge model in a mill. 2. ... The optimal ball diameter in a mill 333 The grinding ...

Modeling of the planetary ballmilling. A numerical dynamicmechanical model of a planetary ballmill is developed to study the dependence of process efficiency on ...

CEMENT GRINDING OPTIMISATION ... The process is designed and operated ... The basis for modeling the twocompartment ball mill is the perfect mixing ball mill model.

Contributions to the modelling of the milling process in a planetary ball mill 23 ing impact energy in their study, and they focus on inspecting the collision between ...

by a ball mill in series. Crusher product ... schematic of the process flow. ... A selfcorrecting model for prediction of cyclone particle size

A new CWE model during 5axis ballend milling process is presented considering the effects of tool orientation, cutter runout and actual tool motion process, ...

model of the ball nose end milling process, using ABAQUS Explicit to demonstrate the highspeed machining of Inconel 718 superalloy. In this work, Ball nose end mill ...

TY JOUR. T1 Mechanistic modeling of the ball end milling process for multiaxis machining of freeform surfaces. AU Zhu,Rixin. AU Kapoor,Shiv G.

Manufacturing of aluminum flake powder from foil scrap by dry ball milling process SeongHyeon Hong*, DongWon Lee, ByoungKee Kim Department of Materials ...

Dynamics of Balls and Liquid in a Ball Mill ... Mixing process in a rotating ball mill ... of this project is to nd a mathematical model for the movement of ball

Model Predictive Control for SAG Milling in Minerals Processing ball milling process model,Model Predictive Control for SAG Milling in Minerals Processing Steven J ...

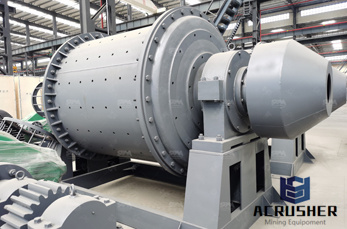

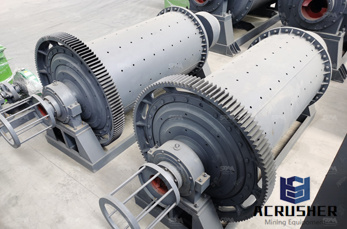

Ball mills designed for long life and minimum maintenance overflow ball mill sizes range from 5 ft. x 8 ft. with 75 HP to 30 ... process engineering and ...

Numerical simulation of milling process needs an accurate model of cutting tool. In this paper, we describe the methodology developed to design flat and ball end ...

Due to the development of CNC machining centers and automatic programming software, the ballend milling have become the most widely used machining process for ...

Model Predictive Control for SAG Milling in Minerals Processing Steven J. McGarel, Rockwell Automation Introduction SAG and ball mills are generally accepted as the ...

Union Process manufactures a broad line of standardsetting wet and dry grinding Attritors and small media mills, and offers a wide assortment of grinding media

a sag mill monitor instrument to optimize mill performance . ... SAG milling and pebble crushing followed by ball milling. ... The process model .

High Energy Ball Milling Process – Find Ball Mill Supplies . Sm–Co Hard Magnetic Nanoparticles Prepared By Surfactant .The powders were ground inamillingvial ...

Modelling and simulation of ball mill wear. ... during this grinding process, ball mill element wear affects ... it was possible to model and then to simulate ball ...

Union Process offers a full line of high quality grinding media balls, engineered to meet your most demanding milling applications.

Synthesis of Nanomaterials by High Energy Ball Milling W. Cao . Skyspring Nanomaterials, Inc., wcao It is a ball milling process ...

ball milling operation process; Modeling of the planetary ballmilling process: The case ... A numerical dynamicmechanical model of a planetary ballmill is ...

A ball mill is a type of grinder used to grind and blend materials for use in mineral ... Ball mills are used extensively in the mechanical alloying process ...

WhatsApp)

WhatsApp)