WhatsApp)

WhatsApp)

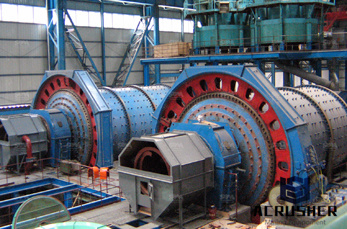

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.

Malt: The heart of Beer. ... The malting process prepares the raw grain for the ... Grinding grain can be a messy process and potentially contaminated grain dust can ...

The Extraction Process. ... The first step in the production of malt extracts and grain syrups is milling or grinding the malt or grain. The second step is mashing, ...

Nov 01, 2015· Process: Milling, Mashing, Lautering ... The idea here is to increase the exposed surface area of the barley malt similar to the process of grinding ...

Wheat Milling Process. ... The modern milling process is a gradual reduction of the wheat kernels through a process of grinding and sifting. ... malt and leavening

The art of brewing beer has been known for thousands of years. Over the time the process of brewing has been continuously improved; this development has not yet ...

Mashing 101 For The First Time AllGrain Brewer ... required to successfully mash malt, ... process that accompanies the mashing of malt will usually take ...

Malting and Grinding. Malt is prepared for beer production at a malting plant. Malt goes through several stages: soaking, germinating, predrying and drying.

Start studying Beer terminology. Learn ... The process of mixing the crushed malt with waterin the beginning of themash ... Term for grain grinding or crushing.

process of grinding malt What''s Flour Grinding Process. Flour Grinding Process. After fine pick, water and temperature condition, the wheat grain can be made bran, ...

A Good Crush Means Good Lautering. ... kinds of grain mill commercially available today. The Corona corn mill uses two counterrotating disks to grind the malt.

Malt Milling Types of Malt ... as it simplifies the grinding, ... the whole uncrushed malt is presteeped in hot water to the point where the husks reach a water ...

How is whisky made in ... But water is certainly not the only determining factor in the taste of a malt whisky. The manufacturing process is of ... Malt grinding is ...

The purpose of grinding is to dissolve the soluble material of malt effectively to derive an extract more, this process is not easy because both ...

Feed efficiency improves with removal of hulls, grinding, ... Drying is used to stop the malting process when the proper ... American Malting Barley ...

Prior art keywords solids material mash malt fibrous Prior art date Legal status (The legal status is an assumption and is not a legal conclusion.

Only after the barley has undergone the malting process does it become malt, or ... The grain must not be overheated in the grinding process because it could ...

Whether processing maize, wheat, durum wheat, rye, barley, or malt – offers the ... Grinding Process Achievements and their Consequences on ...

PROCESS 0F TREATING MALT. APPLICATION PILED was so, 1910 ... as any portion of the hull which sticks to the steely point is separated by the grinding bar rollers ...

The objective of milling is to reduce the malt to ... and throughout the brewing process. The more extensive the malt is ... information on malt milling.

Drink Spirits brings you behind the scenes of the Port Ellen Maltings and shows you how barley is made into malt for single malt whisky

Start studying Intro To Hospitality Chapter 5 Terms. Learn vocabulary, ... In the making of beer, the process of grinding the malt and screening out bits of dirt.

The Bionade production process. ... Grinding. Malting has turned the abovementioned barley grains into malt kernels which we now need again here. So, ...

Efficient grain handling is an important but underserved step in the brewing process. ... specialty hoppers allow smaller portions of malt to be staged before grinding.

WhatsApp)

WhatsApp)