WhatsApp)

WhatsApp)

Population balance approach and energy efficiency . Cement clinker, Ball mill, Dry grinding, Specific energy, Specific selection function, . an accurate measure of ...

Coal Mill Grinding Efficiency | Manganese Crusher. Search coal mill grinding efficiency to find your need. Zenith Mining and Construction Machinery is a global ...

Office of Energy Efficiency Renewable Energy. From Flour to Grits, ... You are here. Home » From Flour to Grits, a WaterPowered Mill Keeps on Grinding.

Energy efficiency in grinding systems, Increasing Thermal Substitution Rate ( TSR) in Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant

Energy Efficiency Comparison in Fine Grinding in the Mining Industry Michel Brissette,, Ing. VP Metallurgy ... energy efficiency than the ISA Mill

This review looks at the basic concepts of grinding mills, ... Grinding Mill; VERTIMILL Grinding Mills ... effective flowsheet and energy efficiency.

ACHIEVEMENT OF HIGH ENERGY EFFICIENCY IN GRINDING MILLS AT SANTA RITA *S. latchireddi 1 and, E. Faria2 1OUTOTEC (USA) .

How does your plant compare? Comminution has long been touted as an energy intensive and inefficient process. The main culprit is the humble grinding mill which ...

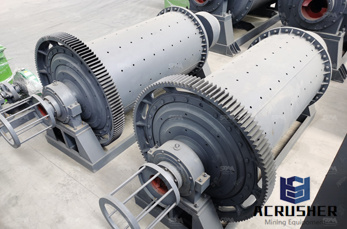

The ball mill crushes materials through the impact and grinding effect of the grinding media. In this process, the steel ball is used a medium of energy to transform ...

Improving Autogenous/SemiAutogenous Grinding Performance and Energy Efficiency with Optimised Pulp Lifter Design S Latchireddi1 ABSTRACT The .

Grinding Efficiency In Ball Mill. Size Reduction Equipment ... What is grinding efficiency? – ball mill. What is grinding efficiency? Energysaving Ball

Barite Grinding Mill, (Shanghai, ... We have developed barite grinding mill with high efficiency and can save energy greatly. Nowadays, ...

What is the effect of low ball % full on grinding efficiency?One of our clients is thinking of the future and has bought a ball mill that will be the right size ...

Outotec Grinding Mills. Optimize grinding mill ... TPL is an environmentally friendly technology used to achieve higher energy efficiency from the grinding mill.

It is difficult to compare the energy efficiency of the regrind ball mill with the IsaMill ... advantage in the improved energy efficiency in coarse grinding, ...

Cement Mill/Final Grinding Process The ... uses a circuit grinding system where a high ... Company Toolkit for Energy Efficiency ...

IMPLEMENTING STRATEGIES TO IMPROVE MILL CAPACITY AND EFFICIENCY THROUGH CLASSIFICATION BY ... capacity and in energy consumption in closed grinding circuits is in ...

Achievement of High Energy Efficiency in Grinding Mills at CEEC. The relative ''efficiency'' of horizontal grinding mills compared to other comminution equipment is ...

Factors Affecting the Efficiency of Ball Mill College Essays ... Ball mill is the key equipment for grinding after the crush process, and it is widely used in the ...

Limestone grinding mill is Clirik energy efficient development and production of ultrafine ore grinding mill equipment, this limestone mill can easily limestone raw ...

PhysicoChemical Aspects of Grinding: ... energy input to the grinding mill. ... If this deformation energy is in. cluded, grinding efficiency can be considered

energy efficency ball mill; The energy efficiency of ball milling in comminution ScienceDirect. If the energy to produce new surface by singleparticle breakage is ...

Xinhai grinding mill has excellent energy saving ability, Xinhai, as ball mill manudactures, the energysaving ball mill up to 30%, great ball mill working principle ...

ACHIEVEMENT OF HIGH ENERGY EFFICIENCY IN GRINDING MILLS AT SANTA RITA *S. Latchireddi1 and, E. Faria2 1OUTOTEC (USA) .

WhatsApp)

WhatsApp)